Table of Contents

How much force does your machine need to move an object safely? This is key when picking a winch. It affects how well the winch can handle different loads.

Getting to know winch ratings is vital. Ratings include line pull capacity and duty cycle. These show how well a winch can work under different conditions.

By understanding these ratings, you can pick a winch that fits your needs. This ensures your winch works safely and reliably.

Key Takeaways

- Winch ratings involve multiple factors, including line pull capacity and duty cycle.

- Understanding winch ratings is crucial for selecting the right winch.

- Decoding winch ratings ensures safe and reliable operation.

- Winch performance ratings help determine the winch’s ability to handle different loads.

- Choosing the right winch requires considering various winch rating criteria.

The Importance of Understanding Winch Ratings

Winch ratings are more than just numbers. They ensure winches work safely and effectively. Knowing these ratings helps pick the right winch for your needs.

Why Ratings Matter for Performance and Safety

Winch ratings affect both performance and safety. A winch rated for 10,000 pounds might only pull 7,500 pounds. This shows how important it is to understand winch performance factors.

Key factors influencing winch performance include:

- The number of layers on the drum

- The type of rope or cable used

- The condition and maintenance of the winch

Common Misconceptions About Winch Capabilities

Many people think a winch’s rated capacity is its maximum load under all conditions. But this is not true. The actual pulling power can be much less, depending on various factors.

For example, rope layers on the drum greatly affect pulling power. As more layers wrap around the drum, the winch’s pulling power drops.

| Layer | Pulling Power |

|---|---|

| 1st Layer | 100% Rated Capacity |

| 2nd Layer | 85-90% Rated Capacity |

| 3rd Layer | 75-80% Rated Capacity |

The Cost of Choosing an Inadequately Rated Winch

Choosing a winch with a low rating can be costly. It can lead to safety risks and financial losses. An under-rated winch may fail, causing accidents or damage to equipment.

The financial implications include:

- Cost of repairing or replacing the winch

- Potential costs associated with accidents or damage

- Lost productivity due to equipment failure

How Are Winches Rated: The Fundamental Criteria

To pick the right winch, knowing how they’re rated is key. Winch ratings depend on several important factors. These factors affect how well a winch performs and how safe it is.

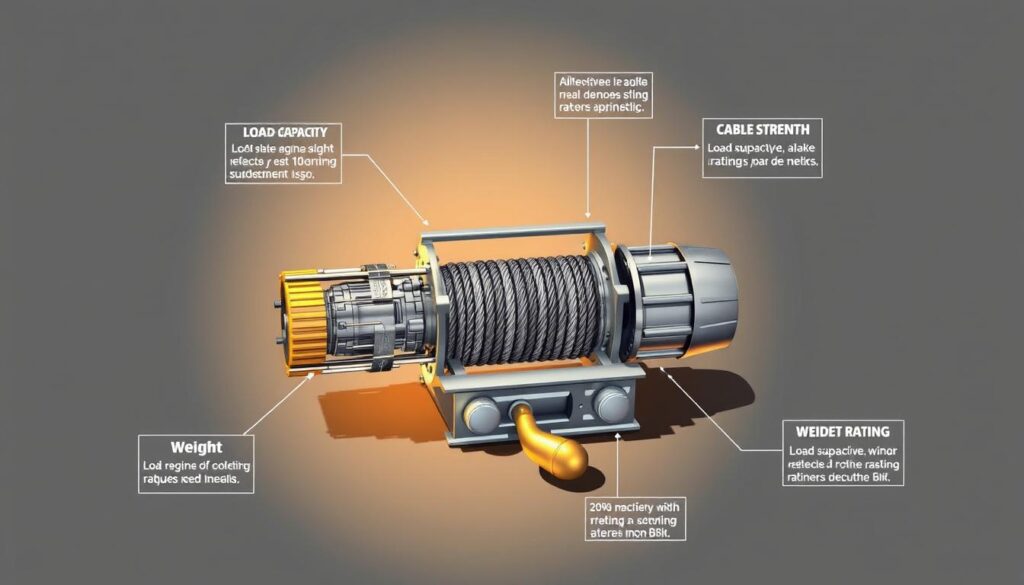

Line Pull Capacity: The Primary Rating Factor

The line pull capacity is the most important factor for winches. It shows the maximum weight a winch can pull. This is usually measured in pounds or kilograms.

When choosing a recovery winch, use the formula GVWR x 1.5 = Minimum Winch Capacity. For example, if your vehicle weighs 5,000 pounds, you need a winch that can handle at least 7,500 pounds.

Static vs. Dynamic Load Ratings

It’s important to know the difference between static and dynamic load ratings. Static load is the weight or force on the winch when it’s not moving. Dynamic load is the force when it’s in use.

Dynamic loads are harder to figure out because they involve acceleration and friction. A winch’s ability to handle these loads is key for recovery or heavy pulling tasks.

Industry Standards and Testing Protocols

Industry standards and testing protocols are crucial for winch ratings. Manufacturers follow these to ensure their winches meet performance and safety standards.

| Standard | Description | Testing Protocol |

|---|---|---|

| SAE J706 | Standard for winch testing and rating | Dynamic load testing |

| ISO 9001 | Quality management system | Auditing and certification |

By grasping these basic criteria, you can choose a winch that fits your needs.

Breaking Down the Line Pull Rating

Choosing the right winch means knowing about the line pull rating. It shows how much weight a winch can pull. The rating changes based on the drum’s fullness and the type of cable or rope used.

First Layer vs. Full Drum Capacity

The line pull rating changes with the drum’s fullness. The first layer of rope has the most pulling power. But, adding more layers reduces this power by about 10-12%.

It’s key to know this to judge a winch’s real power. For example, a winch might pull well at first but not as much when the drum is full. This could mean it’s not strong enough for what you need.

Understanding Pound Force and Newton Measurements

Line pull ratings are in pound-force (lbf) or Newtons (N). Knowing these units helps compare winches and check if they fit your needs. Pound-force is the force needed to speed up a one-pound mass at 32.174 feet per second squared. Newtons are part of the SI system, showing force in kilograms, meters, and seconds.

How Manufacturers Determine Maximum Line Pull

Winch makers figure out the max line pull through design, material strength, and tests. They look at the winch’s mechanical advantage, rope or cable strength, and motor power. They also test the winch to make sure it can handle its rated capacity.

The Impact of Drum Size on Effective Pull

The drum size really matters for a winch’s pull. A bigger drum can hold more rope, which might increase capacity. But, as the drum fills, the pull power goes down. A good winch balances drum size with other factors for the best performance.

Knowing about line pull ratings helps pick the right winch. This ensures it fits your needs and works well in your operations.

Duty Cycle Ratings Explained

The duty cycle rating of a winch is key to understanding its use. It shows how long a winch can work before it needs a break to cool down.

What Is a Duty Cycle in Winch Terms

In winches, the duty cycle is how long it can run before needing a rest. This is important because winches, like electric or hydraulic ones, get hot when working. Running a winch too long can cause it to overheat, leading to poor performance or even breaking.

How Duty Cycle Affects Real-World Performance

The duty cycle of a winch affects how well it works in real life. For example, a winch with a high duty cycle can run longer than one with a low rating. This is key for heavy use, like in industrial or recovery work.

- A higher duty cycle rating means it can run more continuously.

- A lower duty cycle rating means it needs more breaks.

- Duty cycle also affects a winch’s efficiency and lifespan.

Comparing Recreational vs. Industrial Duty Cycles

Recreational winches and industrial winches have different duty cycles. Recreational winches are for occasional use, like pulling out a stuck vehicle, and have lower ratings. Industrial winches, used a lot, have higher ratings for their tough jobs.

| Duty Cycle Characteristics | Recreational Winches | Industrial Winches |

|---|---|---|

| Continuous Operation | Lower capability | Higher capability |

| Heat Management | Basic cooling | Advanced cooling systems |

Cooling Systems and Their Effect on Duty Ratings

Cooling systems are crucial for a winch’s duty cycle. Better cooling lets a winch run longer without overheating. This is because it helps get rid of the heat it makes while working.

Key factors influenced by cooling systems include:

- Enhanced heat dissipation

- Increased continuous operation capability

- Improved overall winch performance and reliability

Motor and Power System Ratings

The motor and power system of a winch are key to its performance. The motor type and power source determine how well it works. They also decide if it’s right for the job.

Electric Winch Power Ratings

Electric winches are rated by their power use and output. Their power rating is in horsepower (HP) or kilowatts (kW). This shows how much work the winch can do.

- Voltage Rating: Electric winches have specific voltage ratings (like 12V, 24V). The voltage affects the winch’s power and what it can use.

- Current Draw: The current draw shows how much electricity the winch uses. It’s important for knowing the electrical load.

Hydraulic Winch Power Specifications

Hydraulic winches use hydraulic systems for their power. They have high power for their size. Their ratings are based on hydraulic pressure and flow rate.

- Pressure Rating: The pressure rating (in PSI or bar) shows the hydraulic pressure the winch can handle.

- Flow Rate: The flow rate (in gallons or liters per minute) shows how fast the winch can work.

Comparing Horsepower and Torque Ratings

When looking at winches, knowing the difference between horsepower and torque is important. Horsepower shows the winch’s work rate. Torque shows its pulling power.

Key Considerations:

- Horsepower: Shows the winch’s work rate.

- Torque: Shows the winch’s pulling power.

Understanding these top winch rating factors and winch rating criteria helps users choose the right winch. This ensures the winch works well and safely for their needs.

Gear Ratio and Line Speed: The Performance Metrics

Understanding gear ratio and line speed is key to judging a winch’s performance. These factors help decide if a winch fits a particular use.

How Gear Ratio Affects Pulling Power

The gear ratio of a winch greatly affects its pulling power. A winch with a high gear ratio can pull a lot but moves slowly. This is because the gear ratio controls the torque on the winch drum.

Example: A winch with a 10:1 gear ratio pulls harder than one with a 5:1 ratio. But it pulls the cable slower.

Line Speed Ratings and Their Practical Implications

Line speed shows how fast a winch can pull in a load. It’s measured in feet or meters per minute. Knowing the line speed is vital for quick tasks. Yet, faster line speeds often mean less pulling power.

Balancing Speed and Power in Winch Selection

Choosing the right winch means finding a balance between speed and power. For heavy tasks, a winch with a high gear ratio is better, even if it’s slower. For quick tasks, a winch with a lower gear ratio and faster line speed is better.

| Application | Preferred Gear Ratio | Line Speed |

|---|---|---|

| Heavy-Duty Recovery | High (e.g., 10:1) | Slow |

| Industrial Use | Medium (e.g., 7:1) | Moderate |

| Recreational | Low (e.g., 5:1) | Fast |

Multi-Speed Winches and Their Rating Complexities

Multi-speed winches are versatile because they can switch between gear ratios. This is great for different tasks where you need both power and speed. But, understanding how they work is complex.

For example, a multi-speed winch might have a high gear ratio for heavy pulling. It can switch to a lower gear ratio for faster speeds when the load is lighter.

Weatherproofing and Environmental Ratings

When picking a winch, knowing its weatherproofing and environmental ratings is key. This ensures it works well in different conditions. Winches face harsh weather like rain, snow, and extreme temperatures. These can affect how well they work and last.

IP Ratings for Water and Dust Resistance

The Ingress Protection (IP) rating shows how well a winch resists water and dust. It has two digits. The first digit is for solid particles, and the second is for liquids. For example, an IP67 winch can handle dust and water up to 1 meter deep.

Understanding IP Ratings:

| First Digit (Solid Particles) | Second Digit (Liquids) |

|---|---|

| 0 – No protection | 0 – No protection |

| 1 – Protection against objects > 50 mm | 1 – Protection against dripping water |

| 2 – Protection against objects > 12.5 mm | 2 – Protection against dripping water when tilted |

| … | … |

| 6 – Dust tight | 7 – Protection against immersion up to 1m |

| 8 – Protection against immersion beyond 1m |

Temperature Range Specifications

Winches work best within certain temperature ranges. Extreme temperatures can harm their motor, cable, and performance. It’s important to choose a winch that fits your expected temperature range.

Corrosion Resistance Classifications

Winches need to resist corrosion, mainly in marine or humid areas. ISO 9227 ratings show how well a winch stands up to salt spray. Winches with strong corrosion resistance are coated or made from materials that fight off saltwater and moisture.

Extreme Environment Certification Standards

Some winches are made for extreme conditions, like explosive atmospheres or dusty areas. Certifications like ATEX for explosive areas or NEMA ratings for North America ensure they’re safe and reliable in tough spots.

Knowing these environmental ratings and certifications helps choose the right winch for your needs. This ensures it’s reliable, safe, and performs well.

Winch Cable and Synthetic Rope Ratings

The performance of a winch greatly depends on its cable or rope. Knowing about winch cable and synthetic rope ratings is key. The type of cable or rope affects the winch’s performance, safety, and how long it lasts.

Steel Cable Strength Specifications

Steel cables are tough and resist wear well. Their strength is measured by breaking strength, the max load they can handle before breaking. Breaking strength is key in picking the right steel cable for a winch.

| Cable Diameter (inches) | Breaking Strength (lbs) | Typical Applications |

|---|---|---|

| 1/4 | 5,400 | Small winches, ATV recovery |

| 3/8 | 12,200 | Medium-duty winches, off-road recovery |

| 1/2 | 21,600 | Heavy-duty winches, industrial applications |

Synthetic Rope Breaking Strength

Synthetic ropes are lighter and safer than steel cables. Their breaking strength is also important, with modern materials offering great strength for their weight. Choosing the right synthetic rope is crucial for the winch’s capacity and use.

- Synthetic ropes are safer if they snap back during failure.

- They are easier to handle and store because they are lighter.

- But, they can be more damaged by abrasion and UV exposure.

How Cable Type Affects Overall Winch Performance

Choosing between steel cable and synthetic rope impacts a winch’s performance. Durability, weight, and safety are important factors. The right choice can make the winch more efficient and reliable.

Maintenance Requirements and Longevity Factors

Regular maintenance is vital for both steel cables and synthetic ropes. This includes checking for damage, cleaning, and proper storage. Knowing how to maintain your winch cable or rope can prevent early wear and ensure top performance.

- Regularly check cables and ropes for damage or wear.

- Clean and lubricate steel cables as the manufacturer suggests.

- Keep synthetic ropes away from direct sunlight when not in use.

Control System and Safety Ratings

Modern winches have advanced control systems and high safety ratings. They are designed to protect the operator, the equipment, and the area around them.

Remote Control Range and Reliability

Remote control is a key feature of winch systems. It lets operators control the winch from a safe distance. The range and reliability of these controls are crucial for safe use.

A reliable remote control system ensures the winch works as expected. This is important, even in tough environments.

Braking System Effectiveness

The braking system is a vital safety feature. It prevents accidents by holding the load securely. Modern winches have advanced braking systems that can be adjusted for different tasks.

Overload Protection Features

Overload protection is key to preventing accidents. It stops the winch from being overloaded. This could cause equipment failure or accidents.

Winches with overload protection can detect when the load is too heavy. They will stop or alert the operator automatically.

Emergency Stop and Failsafe Mechanisms

Many winches also have emergency stop features and failsafe mechanisms. These ensure the winch can stop quickly in emergencies. They add an extra layer of safety for everyone involved.

When choosing a winch, look at the control system and safety ratings. Make sure it meets your needs and safety standards. Key features to check include:

- Reliable remote control systems

- Effective braking systems

- Overload protection

- Emergency stop and failsafe mechanisms

Comparing Top Winch Brands and Their Rating Systems

Choosing the right winch is more than picking a brand. It’s about knowing their rating systems. Each brand rates their winches differently, making it hard to compare.

Warn vs. Smittybilt Rating Methodologies

Warn and Smittybilt are big names in winches. Warn winches are known for their high ratings, based on real-world tests. Smittybilt focuses on durability and rates more conservatively. Knowing these differences helps you choose wisely.

Comparison of Warn and Smittybilt Winch Ratings:

| Brand | Rating Methodology | Key Features |

|---|---|---|

| Warn | Dynamic Rating | High-performance, real-world testing |

| Smittybilt | Conservative Rating | Durability-focused, rigorous testing |

Budget vs. Premium Brand Rating Reliability

Rating reliability varies between budget and premium brands. Premium brands like Warn and Smittybilt invest in thorough testing. Budget brands might not test as much, leading to less reliable ratings.

Consumer Reports show premium brands perform better and are more reliable.

Proprietary Rating Features and What They Mean

Top winch brands have special rating features. These can include advanced diagnostics or specific duty cycle ratings. Knowing these can help pick the right winch for your needs.

Consumer Reports and Independent Testing Results

Consumer reports and independent tests are key when comparing winch brands. They offer real data on performance, reliability, and durability. This helps consumers understand how different winches do in various situations.

A study showed premium brands do better in reliability and performance under extreme conditions.

Application-Specific Rating Considerations

Winch applications vary a lot. Knowing the specific rating needs for each is important. Fields like off-road recovery, industrial operations, and marine environments have unique demands. These demands affect the type of winch and its rating.

Off-Road Recovery Winch Requirements

Off-road recovery winches face tough conditions like mud, water, and extreme temperatures. They need a good IP rating for water and dust protection. The line pull capacity must be enough to handle the vehicle’s weight plus extra resistance.

The formula for pulling a load up an incline is key. It’s Required Pull = (Load Weight x Rolling Resistance) + (Load Weight x Grade Resistance). This formula helps figure out the winch’s needed capacity.

Industrial and Commercial Winch Standards

Industrial winches handle heavy-duty tasks. They need high-duty cycle ratings and strong builds. Standards for these winches include tough testing for durability and performance under load.

Reliability and maintenance are crucial. Features like overload protection and emergency stop mechanisms are essential.

Marine Winch Rating Particularities

Marine winches face special challenges like saltwater corrosion. They need high strength for anchoring and mooring. Corrosion-resistant materials and coatings are vital.

The winch’s design must meet marine operation needs. This includes controlled line speed and handling different ropes or cables.

Understanding these specific rating needs is key. It helps choose a winch that meets its intended use’s demands. This ensures both performance and safety.

How to Calculate Your Specific Winch Rating Needs

Figuring out the right winch rating for your vehicle is key. It’s not just about the vehicle’s weight. You also need to think about where and how you’ll use the winch.

The Gross Vehicle Weight Formula

Start by knowing your vehicle’s Gross Vehicle Weight Rating (GVWR). This is the max weight your vehicle can handle, including you, your stuff, and extra gear. A good rule of thumb is GVWR x 1.5 = Minimum Winch Capacity. This helps ensure your winch can handle recovery safely.

For example, if your GVWR is 5,000 pounds, you’ll need a winch that can handle at least 7,500 pounds. This is just a starting point. You might need to adjust based on other factors.

Accounting for Recovery Conditions and Resistance

Recovery conditions can affect the winch rating you need. Things like the terrain and obstacles can make pulling harder. For example, pulling out of mud requires more force because of the suction.

- Terrain Type: Different terrains offer varying levels of resistance. For example, muddy or sandy terrains are more challenging than firm, dry ground.

- Incline: The steeper the incline, the greater the force required to pull the vehicle.

- Additional Load: If you’re recovering a vehicle with additional load or attached to other objects, this extra weight must be considered.

Safety Margin Calculations

Adding a safety margin to your winch capacity is important. It helps cover unexpected loads or conditions. A safety margin gives extra capacity for unseen obstacles or terrain changes.

Adding 10% to 20% to the minimum winch capacity is common. For a 7,500-pound minimum, a 10% safety margin would be 8,250 pounds.

Tools and Resources for Accurate Estimation

There are many tools and resources to help estimate your winch needs. Online winch calculators can give a quick estimate based on your vehicle and recovery conditions. Also, talking to professionals or experienced users can provide valuable insights for your situation.

- Online Winch Calculators

- Manufacturer Guidelines

- Professional Consultation

By considering these factors and using the right tools, you can find the perfect winch rating. This ensures safe and effective recovery operations.

Conclusion: Making an Informed Winch Selection

Choosing the right winch is key for both performance and safety. Understanding winch ratings helps you pick the right one for your needs. You need to look at line pull capacity, duty cycle, and environmental conditions.

A winch selection guide can help you understand these factors. It’s not about finding the most powerful winch. It’s about finding the right one for its purpose. Whether it’s for recovering a vehicle or hauling heavy loads, the right winch ensures safe and efficient use.

When picking a winch, think about the specific job it will do. Consider the vehicle type, terrain, and load needs. This way, you can find a winch that is reliable, efficient, and safe. With this guide, you’re ready to make a smart winch choice that meets your needs and improves your performance.