Table of Contents

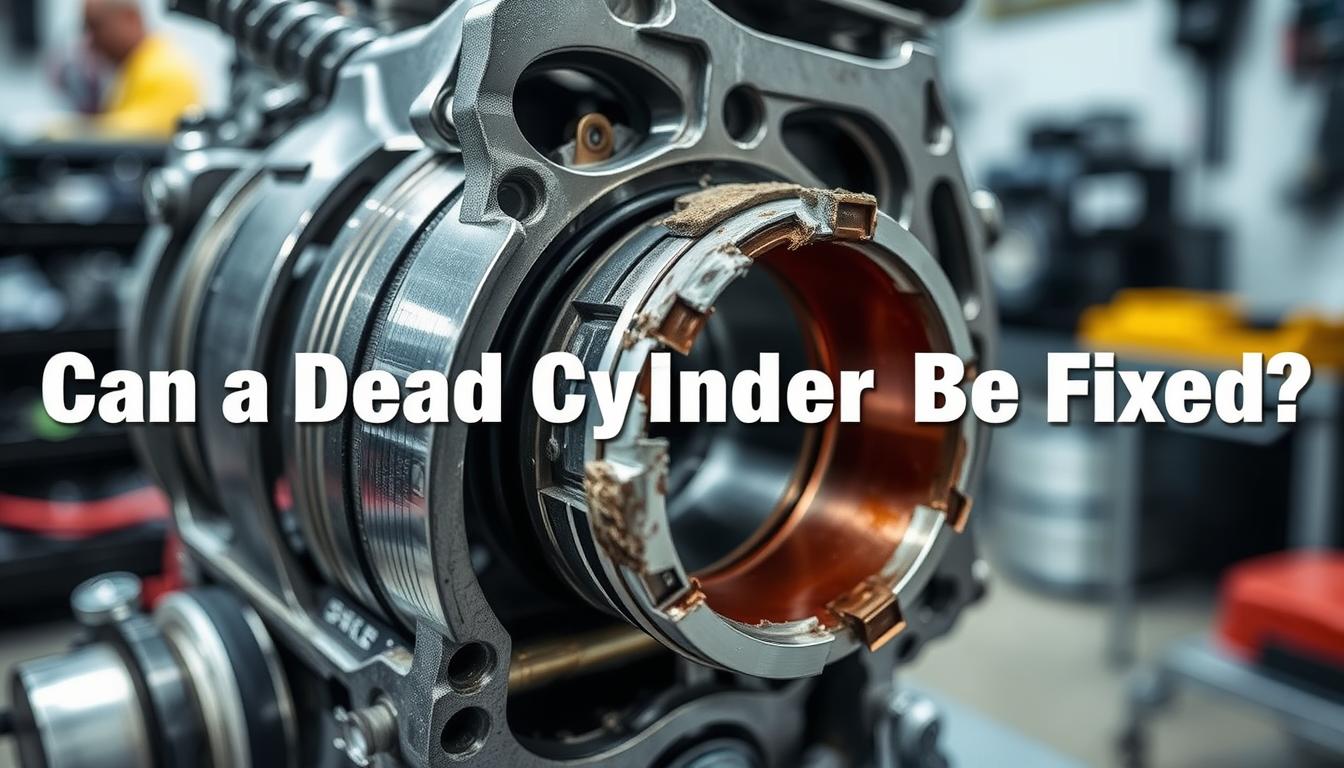

Is your vehicle’s engine performance suffering due to a dead cylinder? This can cause your car to lose power and use more fuel. If not fixed, it could damage your engine even more.

Diagnosing and repairing a dead cylinder is crucial for your engine’s health. We’ll look at how to fix a non-working cylinder. This includes finding the problem, fixing it, and how to prevent it from happening again.

Knowing why and how to fix dead cylinders helps you take better care of your car. It’s important for keeping your vehicle running smoothly.

Key Takeaways

- Diagnosing the cause of a dead cylinder is essential for effective repair.

- Repair options vary depending on the underlying issue.

- Preventive maintenance can help avoid dead cylinders.

- Restoring engine performance improves overall vehicle efficiency.

- Addressing dead cylinders promptly can prevent further engine damage.

Understanding What a Dead Cylinder Is

Engine cylinders are key in the combustion process. Their failure can cause many engine problems. They are where fuel is ignited to make power. Knowing how they work and what happens when they fail is important for fixing engine issues.

Definition and Basic Function of Engine Cylinders

Engine cylinders are where air and fuel mix and ignite, making power. They turn fuel’s chemical energy into mechanical energy for the vehicle. The engine’s performance depends on the cylinders’ work.

How a Cylinder “Dies” or Fails

A cylinder fails when it stops making power. This can be due to bad spark plugs, fuel issues, or mechanical problems. When a cylinder fails, it can’t help with combustion, lowering engine performance.

Impact on Engine Performance and Vehicle Operation

A failed cylinder affects engine performance and vehicle operation. These effects can be both immediate and long-lasting.

Short-term Effects

Short-term, a dead cylinder can make the engine misfire. This leads to rough idling, less power, and the check engine light might come on. These signs need quick attention to avoid more damage.

Long-term Consequences

If ignored, a dead cylinder can cause more serious issues. These include more fuel use, engine damage, and expensive repairs. Misfiring can harm the catalytic converter, and strain can wear down other engine parts.

| Effects | Short-term | Long-term |

|---|---|---|

| Engine Performance | Rough idling, decreased power | Premature wear, potential engine failure |

| Fuel Consumption | Minimal impact | Increased fuel consumption |

| Repair Costs | Potential for minor repairs | Costly repairs, potential for major overhaul |

Knowing the causes and effects of a dead cylinder is key for cylinder misfire repair and engine health. Regular checks and quick diagnosis help avoid big problems.

Common Symptoms of a Dead Cylinder

It’s important to know the signs of a dead cylinder to fix it quickly. A dead cylinder can make your engine run poorly and cause more damage if not fixed.

Engine Misfiring and Rough Idling

Engine misfiring is a common sign of a dead cylinder. This happens when the cylinder can’t ignite the fuel-air mix right. It makes the engine idle roughly and can feel like it’s vibrating or hesitating.

Loss of Power and Acceleration

A dead cylinder means your engine has less power. This affects how well your car accelerates and performs. You might find it harder to speed up or climb hills.

Increased Fuel Consumption

It might seem odd, but a dead cylinder can also make your car use more fuel. The engine tries to make up for the lost power by using more gas.

Check Engine Light and Error Codes

Today’s cars have systems that can spot problems like a dead cylinder. The check engine light might turn on, and you can get error codes like P0300 series with an OBD-II scanner.

Unusual Engine Sounds and Vibrations

A dead cylinder can also cause strange engine noises or vibrations. You might hear knocking or tapping sounds or feel a lot of vibration, mostly when the engine is working hard.

| Symptom | Description |

|---|---|

| Engine Misfiring | Rough idling, hesitation, or vibration |

| Loss of Power | Reduced acceleration, decreased performance |

| Increased Fuel Consumption | Engine consumes more fuel to compensate for lost power |

| Check Engine Light | Illuminated check engine light with specific error codes |

| Unusual Sounds/Vibrations | Knocking, tapping, or excessive vibration |

Knowing these signs can help you spot a dead cylinder early. This can save you time and money on repairs.

Primary Causes of Cylinder Failure

To fix a dead cylinder, knowing why it failed is key. Cylinder failure can come from many sources. These include mechanical wear, ignition system faults, fuel delivery problems, and compression loss.

Mechanical Issues

Mechanical problems often cause cylinder failure. These issues come from different places:

- Worn Piston Rings: Over time, piston rings can wear out, leading to decreased compression and performance.

- Damaged Valves: Valves that are damaged or not sealing properly can cause a cylinder to fail.

- Cylinder Wall Scoring: Scoring or damage to the cylinder wall can lead to leaks and reduced engine performance.

Ignition System Problems

The ignition system is vital for engine operation. Issues in this system can lead to cylinder failure:

- Faulty Spark Plugs: Spark plugs that are worn out or fouled can prevent a cylinder from firing properly.

- Failed Ignition Coils: Ignition coils that fail can prevent the spark plugs from firing, leading to a dead cylinder.

Fuel Delivery Issues

Problems with fuel delivery can also cause cylinder failure. These issues include:

- Clogged or Leaking Injectors: Fuel injectors that are clogged or leaking can disrupt the fuel supply to a cylinder.

- Fuel Pressure Problems: Issues with fuel pressure, whether too high or too low, can affect cylinder operation.

Compression Loss

Compression loss is a big sign of cylinder failure. Causes include:

- Blown Head Gasket: A blown head gasket can lead to compression loss between cylinders or between a cylinder and the engine block.

- Cracked Cylinder Head or Block: Cracks in the cylinder head or engine block can cause significant compression loss and cylinder failure.

Knowing the main causes of cylinder failure is key for fixing them. By finding the root cause, whether it’s mechanical, ignition, fuel, or compression, technicians can fix it. This might include cylinder head repair or other fixes.

Diagnosing a Dead Cylinder

Figuring out if a cylinder is dead needs several steps. Mechanics use old and new methods to find the problem.

Compression Testing Procedures

Compression testing is key to finding a dead cylinder. It uses a gauge to check each cylinder’s pressure. A big drop in pressure in one cylinder means trouble.

- Remove the spark plug wire and spark plug from the cylinder to be tested.

- Thread the compression gauge into the spark plug hole.

- Crank the engine several times to build up pressure.

- Record the highest reading on the gauge.

Cylinder Leakage Testing

Cylinder leakage testing helps find where a dead cylinder comes from. It fills the cylinder with air and listens for leaks.

To do a cylinder leakage test:

- Pressurize the cylinder with compressed air through the spark plug hole.

- Listen for hissing sounds that indicate air escaping.

- Check if the air is escaping through the intake manifold, exhaust system, or crankcase.

Using OBD-II Diagnostic Tools

Modern cars with OBD-II systems offer a lot of info. OBD-II diagnostic tools can read trouble codes and check engine performance.

Professional Diagnostic Methods

For tough cases, pros use special methods.

Borescope Inspection

A borescope inspection lets mechanics see inside the engine. They can look at cylinders, valves, and piston heads without taking the engine apart.

Pressure Testing

Pressure testing checks for leaks in the engine’s cooling system and intake manifold. It helps find issues with cylinder performance.

Identifying Which Cylinder Is Dead

To find the dead cylinder, mechanics start with a scan tool to look for trouble codes. They also do a misfire test to find the bad cylinder.

Can a Dead Cylinder Be Fixed? Exploring Repair Options

Many car owners wonder if a dead cylinder can be fixed. The answer is often yes. Fixing a dead cylinder can be simple or complex, depending on the problem.

Simple Fixes for Minor Issues

For small problems like bad spark plugs or clogged fuel injectors, fixing it is easy. Just replace the spark plugs or clean the fuel injectors. These simple steps can get the cylinder working again without costing much.

Moderate Repairs for Common Problems

Issues like ignition problems or a bit of compression loss need a bit more work. You might need to replace ignition coils or fix vacuum leaks. These tasks are a bit harder but still doable by yourself or a mechanic.

Major Repairs for Serious Cylinder Damage

Severe damage, like a cracked cylinder head or big compression loss, needs big repairs. This could mean replacing the cylinder head, pistons, or rings. These repairs are complex and expensive, needing a pro’s help.

When Cylinder Repair Is Not Possible

Some times, fixing a dead cylinder just isn’t worth it. If the engine is old or the damage is too much, it might be cheaper to get a new engine. The car’s age, condition, and value are key in making this choice.

Factors Affecting Repairability

Several things decide if a dead cylinder can be fixed. These include:

- Engine Age and Condition: Older engines or those with lots of wear might not be worth fixing.

- Extent of Damage: The bigger the damage, the harder and more expensive the fix.

- Vehicle Value Considerations: For cars that aren’t worth much, fixing it might not be worth the cost.

Engine Age and Condition

The engine’s age and condition are key to deciding if it’s worth fixing. Newer engines in good shape are more likely to be worth the repair.

Extent of Damage

It’s important to know how bad the damage is. Small problems can be fixed easily, but big damage needs a lot of work.

Vehicle Value Considerations

The car’s value also matters. If the car isn’t worth much, fixing it might not be the best choice.

In conclusion, fixing a dead cylinder depends on several things. These include the problem’s nature, the engine’s condition, and the car’s value. Looking into repair options can help car owners make the best choice.

Repairing Simple Cylinder Issues

Simple cylinder problems can usually be fixed with basic repairs. This brings back your engine’s performance. It’s key to find out why the cylinder isn’t working right to fix it correctly.

Replacing Spark Plugs and Ignition Coils

Spark plugs and ignition coils that don’t work right often cause cylinder misfires. Swapping them out can fix the problem.

Tools Required

- Spark plug socket

- Torque wrench

- New spark plugs and ignition coils

Step-by-Step Process

- Find the spark plugs and ignition coils.

- Take off the spark plug wire or ignition coil.

- Use a spark plug socket to take out the old spark plug.

- Put in a new spark plug and attach the spark plug wire or ignition coil back.

Cleaning or Replacing Fuel Injectors

Fuel injectors that are clogged or dirty can also cause cylinder misfires. Cleaning or swapping them out can help your engine run right again.

| Method | Description | Tools Required |

|---|---|---|

| Cleaning | Use a fuel injector cleaning kit to get rid of debris. | Fuel injector cleaning kit |

| Replacing | Put in new fuel injectors. | New fuel injectors, fuel injector socket |

Addressing Minor Compression Issues

Small compression leaks can be fixed by tightening loose parts or replacing old ones.

Fixing Vacuum Leaks

Vacuum leaks can lead to engine misfires and lower performance. Checking and fixing vacuum hoses and connections can solve these problems.

Tackling More Complex Cylinder Repairs

Engine cylinders can fail in many ways, needing detailed repairs. These failures can cause big problems like less power, bad fuel use, and engine breakdown. Fixing these issues needs deep knowledge of engines and the skill to find and fix problems.

Valve Adjustment and Replacement

Valves are key for engine work, controlling air and fuel flow and exhaust. Worn or damaged valves can lead to engine troubles, like misfires and poor performance.

Signs of Valve Problems

Signs of valve trouble include odd engine sounds and lower performance. If ignored, these issues can damage the engine more.

Repair Process Overview

Fixing or replacing valves involves several steps. First, remove the cylinder head. Then, check the valves for damage. Next, adjust or replace them as needed. This job needs special tools and engine knowledge.

Head Gasket Replacement

The head gasket seals the cylinder head to the engine block. It stops leaks of coolant, oil, and gases. A failed head gasket can cause overheating and engine misfires.

Symptoms of Head Gasket Failure

Signs of a bad head gasket include overheating, white smoke from the exhaust, and coolant leaks. Finding this problem often needs a visual check and special tests.

Repair Complexity and Considerations

Replacing a head gasket is a tough job. It involves removing the cylinder head and checking for damage. Then, a new gasket is installed. This repair needs careful attention and engine knowledge.

Cylinder Head Repair or Replacement

Repairing or replacing the cylinder head is needed when it’s damaged. The choice depends on how bad the damage is.

| Repair Type | Description | Complexity Level |

|---|---|---|

| Cylinder Head Resurfacing | Resurfacing the cylinder head to restore its flatness. | Moderate |

| Cracked Cylinder Head Repair | Repairing cracks in the cylinder head using welding or other techniques. | High |

| Cylinder Head Replacement | Replacing the entire cylinder head with a new one. | High |

Intake and Exhaust System Repairs

The intake and exhaust systems are vital for engine performance. Problems like leaks, clogs, or damage can hurt engine efficiency and performance.

Fixing or replacing parts of these systems needs understanding of their function and problem-solving skills. Common fixes include replacing faulty sensors, fixing leaks, and cleaning or replacing clogged parts.

Major Engine Overhaul for Severe Cylinder Damage

Severe cylinder damage often needs a full engine rebuild. This ensures the engine lasts longer. The process includes several key steps to improve the engine’s performance and efficiency.

Piston and Ring Replacement

Replacing pistons and rings is a crucial part of an engine rebuild. Worn-out parts can lower engine performance and increase oil use. New parts can greatly improve the engine’s health.

Piston replacement is needed when pistons are damaged or too worn. Ring replacement is also key, as worn rings can cause poor sealing and loss of compression.

Cylinder Boring and Honing

Cylinder boring and honing restore the cylinder walls to their original state. Cylinder boring makes the cylinder bigger for oversized pistons. Honing smooths the walls for better piston ring sealing.

Complete Engine Rebuild Considerations

A complete engine rebuild is a big job that replaces major parts. It’s important to weigh the costs and benefits of such a rebuild.

When a Rebuild Makes Sense

A rebuild is wise when the engine is badly damaged but the rest of the car is good. It’s also a good choice if the rebuild cost is less than a new engine.

Rebuild Process Overview

The rebuild process starts with taking the engine apart. Then, it involves inspecting and cleaning parts, replacing damaged ones, and putting everything back together. This job needs special tools and knowledge.

Engine Block Repair Techniques

The engine block is the engine’s base, and fixing it needs special techniques. Common repairs include fixing cracks, resurfacing the block, and replacing damaged parts.

Engine rebuild experts say, “A successful rebuild needs careful attention and a deep understanding of engine mechanics.”

| Rebuild Component | Description | Importance |

|---|---|---|

| Piston and Rings | Replacement of worn-out pistons and rings | High |

| Cylinder Boring | Enlarging cylinders for oversized pistons | High |

| Honing | Smoothing cylinder walls for proper sealing | High |

DIY vs. Professional Cylinder Repair

When your cylinder dies, you must decide if you’ll fix it yourself or get a pro. This choice depends on your skills, the repair’s complexity, and your tools.

What You Can Safely Fix Yourself

Simple problems like bad spark plugs or clogged fuel injectors might be DIY-friendly. These tasks need basic tools and some engine knowledge.

Required Tools and Knowledge

Before starting a DIY fix, make sure you have the right tools and know your engine. You’ll need a spark plug socket, fuel injector cleaner, and a compression tester.

Safety Considerations

Working on your car is risky. Always check your manual, wear safety gear, and keep your area clear. Never work under a vehicle supported only by a jack.

When to Seek Professional Help

For big problems like a cracked cylinder head or major compression loss, get a pro. They have the tools and know-how for tough engine fixes.

“For complex engine repairs, having the right tools and experience is crucial. It’s not just about fixing the immediate problem but also ensuring that the repair is done correctly to prevent future issues.”

Finding a Qualified Mechanic for Cylinder Repair

To find a good mechanic, ask people you trust, check online, and look for ASE certifications. A skilled mechanic will give you a clear diagnosis and repair estimate.

Questions to Ask Your Mechanic

- What is the cause of the cylinder failure?

- What repairs are necessary to fix the issue?

- Can you provide a detailed estimate of the costs involved?

- What is the warranty on your repairs?

Choosing between DIY and a pro can save you time, money, and stress. Knowing your limits and the repair’s complexity helps you make the right choice for your car.

Cost Analysis of Cylinder Repair Options

Knowing the cost of fixing a dead cylinder is key for car owners. The price can change a lot based on the problem and the repair needed.

Price Range for Minor Repairs

Small fixes, like replacing spark plugs or ignition coils, are cheaper. They cost between $100 and $500. These jobs are simple and done fast.

Expenses for Moderate Cylinder Work

Dealing with bigger issues, like fuel injector cleaning or minor compression problems, costs more. It’s between $500 and $2,000. These tasks need more work and special tools.

Major Repair and Engine Rebuild Costs

Big repairs, like engine rebuilds or replacing cylinder heads, are pricey. They can cost from $2,000 to $10,000 or more. This depends on the damage and the car’s type.

Cost-Benefit Analysis: Repair vs. Replacement

Deciding to fix or replace a dead cylinder needs a cost-benefit analysis. Sometimes, fixing it might cost as much as the car itself. In that case, replacing might be cheaper.

Insurance Considerations for Major Engine Work

For big engine fixes, check your insurance. Some policies might cover these costs, if the damage was from a covered event.

Understanding the costs of fixing a cylinder helps car owners make better choices about repairs.

Real-World Case Studies of Cylinder Repairs

Real-world case studies show us the challenges and solutions of cylinder repairs. They highlight the complexity of engine repairs. They also give us insights into solving problems effectively.

Simple Fix Success Stories

Many cylinder issues can be fixed with simple repairs. For example, a car owner had a misfiring engine. It was found to be a faulty spark plug in one cylinder. Replacing the spark plug fixed the problem, making the engine work right again.

This shows how important it is to do a thorough check before fixing anything.

Complex Repair Scenarios

Not all repairs are easy. A car with a cracked cylinder head needed a new head. The new head was made to fit the engine perfectly. This shows the precision needed in complex repairs.

“The most challenging cylinder repair I’ve encountered involved a severely damaged engine block. Rebuilding the engine from scratch was the only viable solution.” – Expert Mechanic

When Repairs Failed to Solve the Problem

There are times when repairs don’t fix the problem. A car had misfires after replacing spark plugs and ignition coils. It turned out a faulty fuel injector was the cause. Replacing it fixed the issue.

This shows how important it is to do a complete check.

Lessons Learned from Difficult Cases

Hard repair cases teach us a lot. One important lesson is to look at the engine’s overall condition when fixing cylinder issues. A detailed table comparing different repair methods can help us find the best way to fix things.

| Repair Approach | Success Rate | Cost |

|---|---|---|

| Simple Fixes | 80% | $200-$500 |

| Complex Repairs | 90% | $1000-$3000 |

| Engine Rebuild | 95% | $3000-$6000 |

By looking at these case studies, DIY fans and mechanics can learn a lot about fixing cylinder problems.

Preventing Future Cylinder Problems

To avoid costly repairs, it’s key to take steps to prevent cylinder failure. By following a few simple practices, you can keep your engine’s cylinders running longer. This helps maintain your engine’s performance.

Regular Maintenance Practices

Regular maintenance is vital for preventing cylinder problems. Stick to your scheduled maintenance to keep your engine in top shape.

Oil Change Schedules

It’s important to follow the oil change schedule closely. Fresh oil helps reduce wear on the cylinders. Oil changes are usually needed every 5,000 to 7,500 miles, depending on your vehicle and oil type.

Tune-Up Recommendations

Regular tune-ups are essential. They involve checking and replacing spark plugs, inspecting ignition coils, and ensuring the fuel system works well. These steps help prevent misfires that can harm cylinders.

Proper Driving Habits

Your driving habits greatly affect your engine’s health. Try to avoid extreme driving, like rapid acceleration and high speeds. This reduces stress on the engine cylinders.

- Avoid hard acceleration and braking

- Maintain a consistent speed when possible

- Avoid over-revving the engine

Quality Fuel and Oil Considerations

Using high-quality fuel and synthetic oil helps your engine run better. It reduces the risk of cylinder damage. Always use fuel and oil that match your vehicle’s manufacturer’s recommendations.

Early Warning Signs to Watch For

Knowing the early signs of cylinder problems can help you fix issues before they get worse. Listen for unusual engine noises and watch for signs of decreased performance, like misfires or rough idling.

Conclusion

Fixing a dead cylinder is possible for many car owners. Knowing why cylinders fail and spotting symptoms early helps. This way, you can quickly fix your engine’s performance.

There are several ways to find out if a cylinder is dead. You can use compression tests or OBD-II tools. Once you know the problem, you can choose from simple fixes like spark plug replacement. Or, you might need to replace the cylinder head or rebuild the engine.

Fixing a cylinder quickly is key. It stops more damage and gets your engine running right. Knowing your repair choices is important, whether it’s a small fix or a big engine job.

Often, a dead cylinder can be fixed, and your engine’s performance can come back. By using the right repair methods and keeping up with car care, your engine will run well and efficiently.