Table of Contents

Selecting the best automotive primer for bare metal is the single most important decision you’ll make when restoring a vehicle or performing bodywork. This initial layer between your car’s vulnerable metal surface and its beautiful topcoat determines not just how good your paint job looks, but how long it lasts. A quality primer acts as an indispensable shield, preventing rust and ensuring your paint adheres properly for years to come. This comprehensive guide will demystify the world of automotive primers, providing you with the knowledge to choose and apply the perfect primer for your project.

Many enthusiasts pour their budget into expensive topcoats while cheaping out on primer—a critical mistake that can lead to peeling, bubbling, and rust bleeding through. The truth is, without the right foundation, even the most premium paint will fail prematurely. Understanding the different types of primers, their specific applications, and proper preparation techniques will save you from costly re-dos and ensure a professional, lasting finish.

Why You Absolutely Need Primer on Bare Metal

Primer is far more than just an extra step in the painting process; it’s a multi-functional foundation system that addresses several critical needs simultaneously.

Corrosion Protection: Your First Line of Defense

Bare metal is incredibly susceptible to oxidation and rust formation when exposed to moisture and air. Primer creates a protective barrier that seals out environmental contaminants . Epoxy primers, in particular, are formulated with resins that provide excellent corrosion resistance, essentially encasing your metal in a protective shell that prevents rust from forming underneath your paint job .

Superior Adhesion: The Glue for Your Paint

Paint alone doesn’t bond well to smooth metal surfaces. Primer is specifically engineered with adhesion-promoting properties that “bite” into the metal while providing a textured surface for the topcoat to grip . This strong bond prevents peeling, flaking, and lifting of your paint over time, especially important for vehicles exposed to temperature variations and vibration.

Surface Imperfection Control

Even meticulously prepared metal can have microscopic imperfections, sanding marks, or slight variations. Primer helps fill these minor flaws and creates a uniform surface . High-build primers take this a step further, allowing you to build thickness to level out small dents and scratches that might otherwise be visible through your final paint .

Understanding Primer Types: A Detailed Comparison

Not all primers are created equal, especially when it comes to bare metal applications. The automotive primer market offers several distinct technologies, each with specific strengths and ideal use cases.

Epoxy Primer: The Gold Standard for Bare Metal

Epoxy primer is widely regarded as the premium choice for bare metal protection due to its exceptional durability and sealing capabilities.

Composition and Technology: Epoxy primers are two-component products typically consisting of epoxy resins and polyamide hardeners that chemically bond to create an incredibly tough, impermeable barrier . This chemical reaction creates a finish that’s much more durable than single-component products.

Key Advantages:

- Superior corrosion resistance creates an excellent moisture barrier

- Excellent adhesion to various substrates including steel, aluminum, and fiberglass

- Forms a hard, durable base that resists chipping and damage

- Can be applied over properly prepared surfaces including fillers and factory finishes

Limitations to Consider:

- Limited sandability once fully cured compared to other primers

- Requires precise mixing of two components

- Shorter pot life after mixing compared to some other options

Best Applications: Epoxy primer is ideal for complete vehicle restorations, underside components, areas prone to moisture exposure, and as a sealer over body fillers . Many professionals use it as the initial coat on all bare metal surfaces.

Self-Etching Primer: The Bare Metal Biter

Self-etching primer uses acid technology to create a strong mechanical and chemical bond with bare metal surfaces.

Composition and Technology: Etch primers contain phosphoric acid or other acidic components that literally “etch” microscopic pores into the metal surface . This etching action creates a physical bonding structure that provides exceptional adhesion.

Key Advantages:

- Unparalleled adhesion to bare metal through chemical etching

- Quick drying time speeds up the repair process

- Eliminates need for metal conditioner on properly prepared surfaces

- Excellent for non-ferrous metals like aluminum and galvanized steel

Limitations to Consider:

- Limited corrosion protection compared to epoxy primers

- Not suitable as a final primer before paint—requires a topcoat of epoxy or urethane primer

- Should not be applied over body filler or existing paint

- Thinner film build doesn’t fill imperfections well

Best Applications: Self-etching primer excels as an initial coat on freshly prepared bare metal, particularly in spot repairs and on aluminum panels . It’s often used in conjunction with other primers for a complete system.

Urethane Primer: The Versatile Performer

Urethane primers, particularly high-build versions, offer excellent filling and sanding characteristics for achieving show-quality finishes.

Composition and Technology: These two-component primers use urethane resins that provide flexible yet durable films. High-build versions contain higher solid content that allows for thicker application without sagging .

Key Advantages:

- Excellent sandability makes block-sanding to perfection easier

- High-build formulations fill sand scratches and minor imperfections

- Good flexibility resists cracking and chipping

- Compatible with various topcoats including basecoat/clearcoat systems

Limitations to Consider:

- Less effective corrosion protection compared to epoxy

- Typically requires epoxy underneath for maximum corrosion protection on bare metal

- Usually requires sanding before topcoat application

Best Applications: Urethane primers are perfect as a secondary primer over epoxy for final surface leveling, complete repaints where surface imperfections need addressing, and custom paint jobs requiring flawless substrates .

Table: Automotive Primer Types Comparison for Bare Metal

| Primer Type | Best For | Corrosion Protection | Adhesion | Sanding | Application Notes |

|---|---|---|---|---|---|

| Epoxy Primer | Complete restorations, rust protection, sealer | Excellent | Excellent | Poor once cured | Apply directly to bare metal; can topcoat or use as sealer |

| Self-Etching Primer | Initial bare metal adhesion, aluminum, spot repairs | Fair | Excellent | Fair | Always top with epoxy or urethane primer; not for filler |

| Urethane Primer | Final surface leveling, filling imperfections | Fair | Good | Excellent | Use over epoxy on bare metal; requires sanding before paint |

The Critical Choice: 1K vs. 2K Primers

Understanding the difference between 1K and 2K primer systems is crucial for professional results.

1K (One-Component) Primers

1K primers come ready to use straight from the container without mixing . These are typically found in aerosol cans and air-dry through solvent evaporation.

Pros:

Cons:

- Less durable and chemically resistant

- Can be dissolved by solvents in topcoats

- Shorter lifespan and protection

- Not recommended for professional-quality finishes

2K (Two-Component) Primers

2K primers consist of a base component and a separate hardener that must be mixed before application . The chemical reaction between components creates a much more durable finish.

Pros:

- Superior chemical resistance and durability

- Harder, more protective finish

- Better adhesion and corrosion protection

- Professional, long-lasting results

Cons:

For bare metal applications, 2K primers are overwhelmingly recommended for their superior protection and durability . The chemical cross-linking that occurs during curing creates a much more robust barrier against moisture and corrosion.

Surface Preparation: The Foundation of Success

Proper surface preparation is arguably more important than the primer selection itself. Even the best primer will fail if applied to improperly prepared metal.

Comprehensive Metal Cleaning

Begin by thoroughly removing all contaminants:

- Degrease using a dedicated wax and grease remover

- Remove oils and residues with appropriate cleaners

- Wipe down with clean cloths to prevent contamination

- Avoid silicone-based products that can cause fish-eyes in paint

Rust Removal Techniques

Complete rust removal is non-negotiable:

- Mechanical removal using sandblasting, grinding, or sanding

- Chemical treatments for hard-to-reach areas

- Inspect thoroughly for any remaining rust spots

- Feather edges of any remaining pits or imperfections

Final Surface Preparation Steps

- Sand entire surface with 180-320 grit sandpaper

- Scuff shiny areas to create mechanical adhesion points

- Remove all sanding dust with tack cloths and air guns

- Final cleaning with wax and grease remover immediately before priming

Professional Application Techniques

Proper application ensures maximum primer performance and protection.

Mixing and Reduction

- Follow manufacturer instructions precisely for mixing ratios

- Use accurate measuring tools—not guesswork

- Stir thoroughly to ensure even distribution of components

- Strain primer through a filter to remove contaminants

- Observe pot life and don’t use material beyond its working time

Spray Gun Setup and Techniques

- Use appropriate nozzle size (typically 1.6-1.8mm for primer)

- Set correct air pressure (usually 25-30 PSI at the gun)

- Maintain consistent distance (6-8 inches from surface)

- Apply overlapping passes (50% overlap for even coverage)

- Watch for sags and runs—apply multiple thin coats rather than one heavy coat

Recommended Application Process

- Apply one medium mist coat to establish initial adhesion

- Follow with two medium-wet coats with proper flash times between

- Build to recommended film thickness without applying too heavily

- Allow proper flash time between coats as specified

- Observe full cure time before sanding or topcoating

Curing, Sanding, and Topcoating

Understanding Cure Times

- Flash time: 5-15 minutes between coats (temperature dependent)

- Sanding cure: 1-4 hours for guide coating and blocking

- Full cure: 12-24 hours before applying some topcoats

- Recoat window: Often 24-72 hours for easiest sanding

Sanding Techniques for Perfect Surfaces

- Use guide coat to identify high and low spots

- Start with appropriate grit (180 for heavy shaping, 320-400 for final)

- Use blocking boards for flat surfaces to prevent waves

- Change paper frequently for efficient cutting

- Inspect surface from multiple angles with raking light

Topcoating Considerations

- Apply within recoat window for best adhesion between layers

- Seal porous primer surfaces before basecoat application

- Follow manufacturer recommendations for primer/topcoat compatibility

- Consider tinting primer toward final color for better coverage

Troubleshooting Common Primer Problems

Even with careful application, issues can arise. Here’s how to address common problems:

Poor Adhesion

- Cause: Insufficient surface preparation or contamination

- Solution: Strip and重新准备surface, ensure proper cleaning

Fish-Eyes

- Cause: Silicone contamination on surface

- Solution: Thorough cleaning with silicone remover, may require sealer

Sand-Throughs

- Cause: Uneven application or aggressive sanding

- Solution: Spot-prime bare areas before topcoating

Orange Peel

- Cause: Improper spray technique, viscosity, or air pressure

- Solution: Adjust technique, proper reduction, sand and recoat if severe

Building a Complete Primer System

For maximum protection and the finest finish, many professionals employ a multi-layer primer system:

- Initial Metal Treatment: Self-etching primer on bare metal for adhesion

- Corrosion Protection: Epoxy primer as a sealer and moisture barrier

- Surface Refinement: High-build urethane primer for imperfection filling

- Final Sealing: Epoxy or dedicated sealer primer before topcoat

This systematic approach addresses all aspects of substrate preparation: adhesion, corrosion protection, and surface refinement.

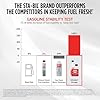

Product Recommendations and Brand Considerations

While specific product choices depend on your location and budget, several brands consistently receive praise from professionals and enthusiasts:

- SPI Epoxy Primer: Frequently recommended in automotive forums for its user-friendliness and excellent results

- PPG Epoxy Primer: A professional standard known for consistent performance

- Nason Ful-Poxy: Quality results at a more accessible price point

When selecting products, consider purchasing from suppliers who offer technical support and detailed product data sheets to guide your application.

Conclusion: Building the Perfect Foundation

Choosing the best automotive primer for bare metal ultimately depends on your specific project requirements, but for most applications, a 2K epoxy primer provides the optimal balance of corrosion protection, adhesion, and durability. For maximum protection, a system approach using self-etching primer followed by epoxy delivers exceptional results.

Remember that proper surface preparation and application technique are just as important as product selection. Investing time in meticulous preparation and using quality 2K products will yield professional, long-lasting results that protect your vehicle for years to come.

Your primer choice establishes the foundation for everything that follows—make it count by selecting products and techniques that match your project goals and quality expectations. The effort you put into proper priming will be reflected in the quality and longevity of your final finish.